We often get people reaching out to us, hoping to get information on an old OPS INC can they purchased. Sometimes, the can is easy to identify because it has a specific model designation, like “12th Model” or “15th Model.” But other times, we encounter what we call a “Seberger Special.”

Author Archives: Brian Sanders

The 7×7 Collars are a new take on an old Allen Engineering product. Formerly known as the M4 Collar, we renamed them to avoid confusion with the M4 suppressors.

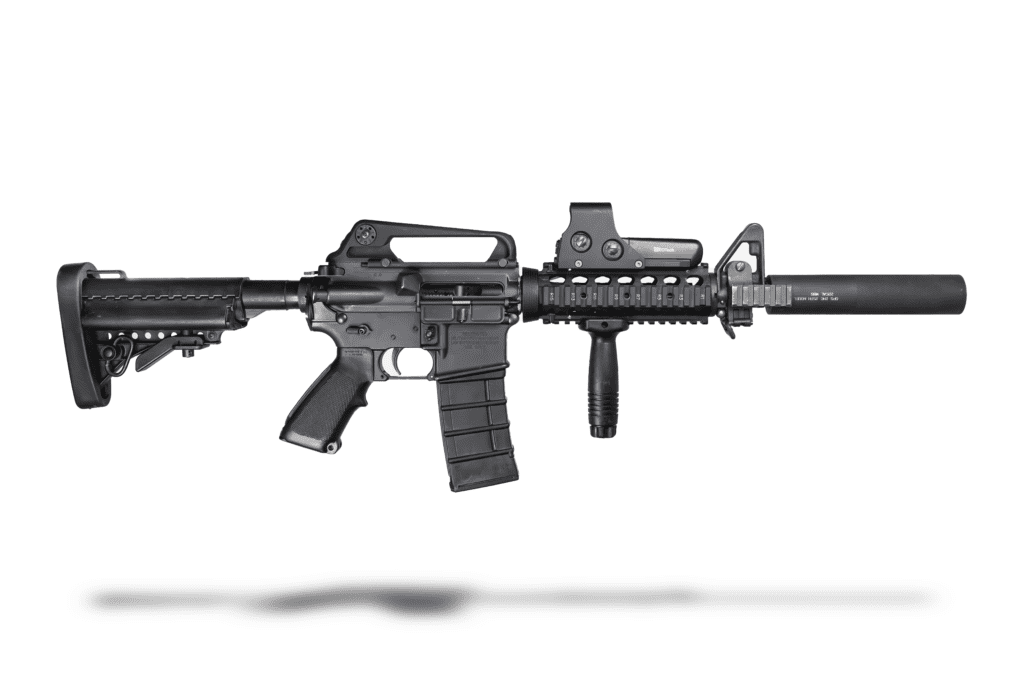

The OPS INC™ 3 piece collar, often referred to as the Gordon Collar, was designed originally for use with the issued M4 rifles of the 90s. It allowed the M4 suppressor to be installed on a 14.5″ barrel with carbine gas system. The clearance cuts on the bottom allow it to be used with an FSB and clear the bayonet lug, however an FSB is not required for use. The 3 piece M4 collar has since become an iconic part of many clone rifles of the era.

On this post we wanted to provide you access to the original Allen Engineering website using the Wayback Machine.

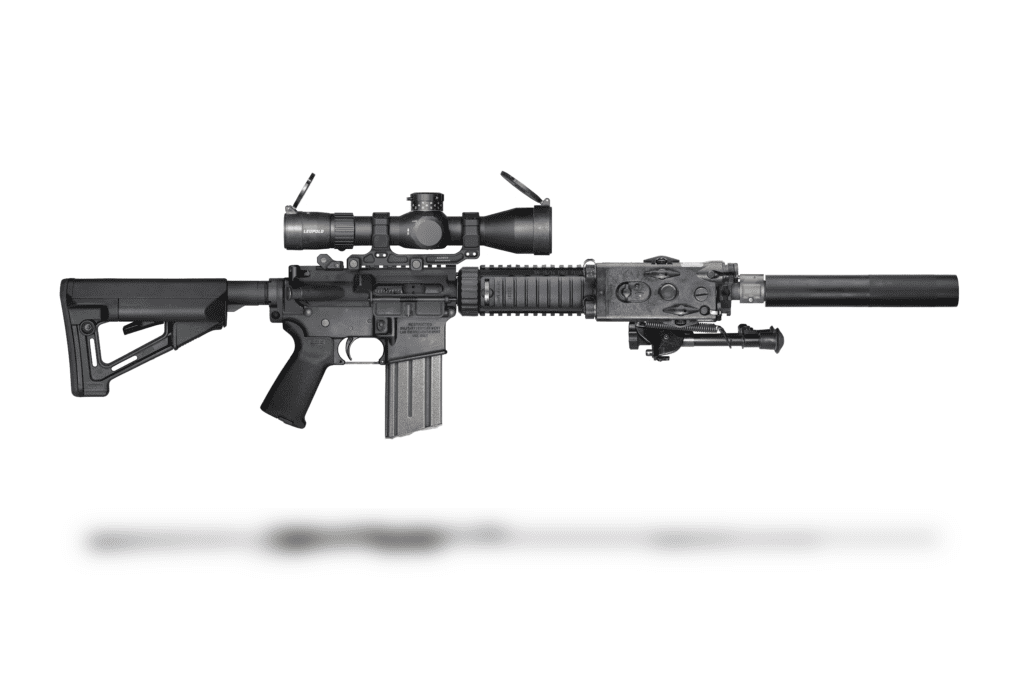

The NSW Recce was born from NSW optimizing the MK12 Mod 1 to be smaller and lighter while not significantly sacrificing on precision. We recently got to talking with Craddock about how great the Recce platform is and how we can help modernize it. From that conversation a new 15.1″ Recce barrel was born.

his year we will be doing another build competition. The winner will get to choose a free AE suppressor for us to send to them.

While our suppressors have stayed relatively the same from OPS INC to present day, there is one difference that can be observed, its coating. From how the coating was applied to the colors that were used, AE suppressors can sometimes look different from one another. Just like other aspects of AE, there is a history to the colors of the suppressors.

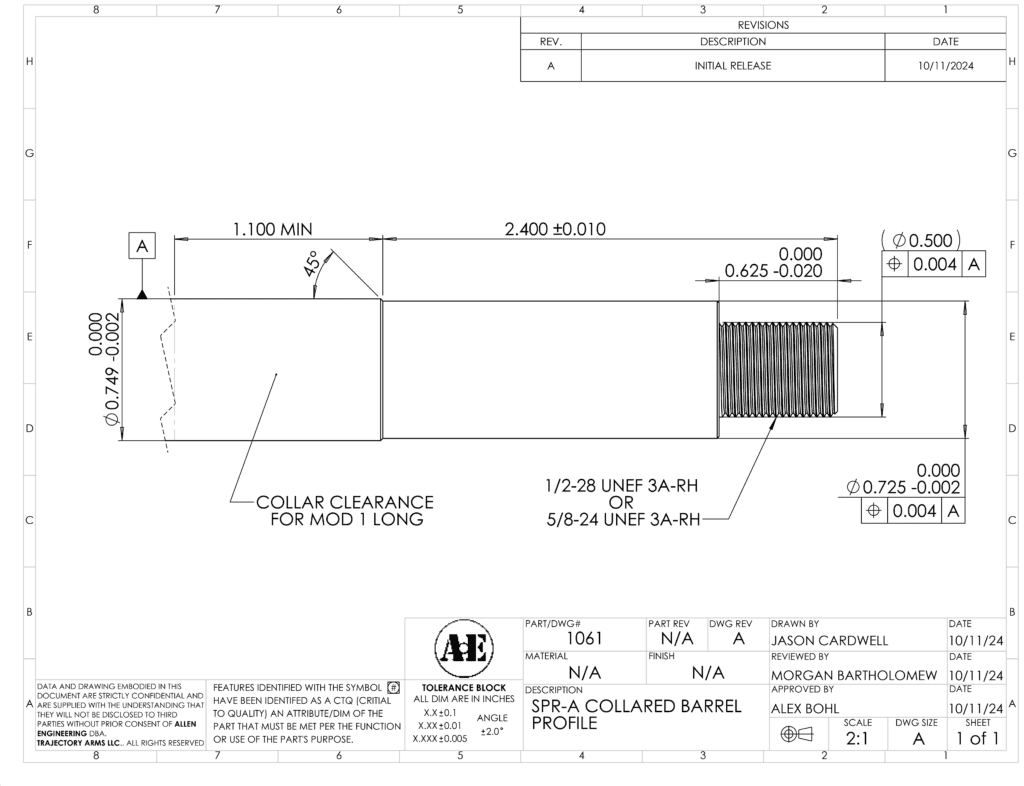

The day has finally arrived! We are publishing barrel prints for mounting Allen Engineering suppressors. No longer will you need to dig through AR15.com to find old AE prints. Thank you all for your patience.

We recently received a cool rifle from Sleipnir The Horse and I wanted to go over it with yall.